PRODUCT

Hyper-connection & Hyper-intelligence

Control System Leader

- PRODUCT

- Gate Valve

Gate Valve

Hyper-connection & Hyper-intelligence Control System Leader

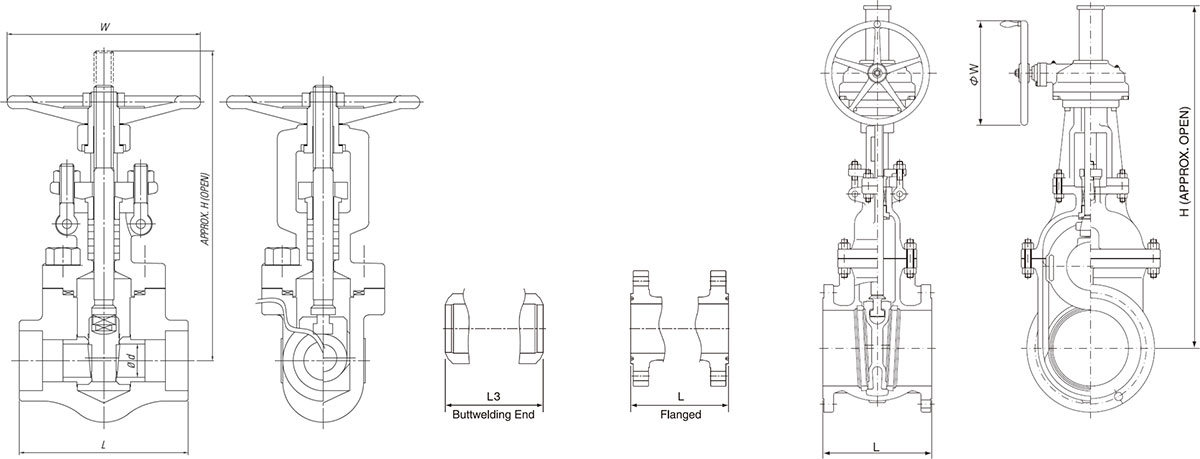

- PARALLEL SLIDE GATE VALVE

-

- The disks (parallel) are in two halves separated by spring and are urged into contact with the opposing seat in the closed position by a spring.

- Advantage to this design is that thermal expansion in the valve does not forces the Gate tighter into the seats.

- As this valve closes, the disk slides across the seats until it bottoms out. So, it does not tighter in the full closed position

- This valve should equip with Equalizing Pipe Line valve certainly. An equalizing pipe line allows the relief of fluid which might otherwise become trapped in the body chamber space (Body cavity) of the valve body.

- CHARACTERISTICS AND MERITS

-

- Gate valves are used for on-off Service.

- Gate Valve are straight-through flow valves which provide positive shutoff with

- minimal pressure drop (Low flow resistance coefficient) and flow turbulence. Large size valves with short end to end to are acailable.

- Overcome the thermal expansion problems due to the increased temperature with applying the flexible wedge disk or parallel slide disk for high temperature conditions

- Gate valve installations should always be made with consideration for the potential of bonnet over-pressurization caused by fluids which may become entrapped in the bonnet of a closed valve. Where this possibility exists, it is the user's responsibility to insure that proper venting is installed.

- Excellent performance of open/close operations and fluid control capabilities,

- Gate valves may be installed without consideration for the direction of flow, they are not recommended for use in a partially open, throttling position which are caues for erosion, noise and excessive wear.

- General Specification

-

Size Range 1/2" ~ 36" (other sizes are available) Pressure Range ASME 150 ~ 4500#, PN 10 ~ 420 Temperature Range -196 ~ 592℃ according to the material spec. Option : 815℃ Body Materials A216 WCB, A217 WC6, WC9, C12A

A351 CF8, CF8M, CF3M

A182 F51, F91, Inconel, Titanium & othersTrim Materials 316, 316L, 321, 410, 420(J2), 440C, 630, XM-19

Inconel. W-Co. Overay, Titanium & othersTrim Design Flexible Wedge, Parallel Slide, according to the Counsultant factory Bonnet Style Bolted, Pressure Seal, Welded, None-bonnet and others Seak Leakage Class EN 12266-1 Rate "A", MSS SP-61, according to the spec. Seak Leakage Class EN 12266-1 Rate "A", MSS SP-61, FCI 70-2. Class VI, according to the spec. Applicable Actuators OS&Y Handwheel, Worm Gear, Pneumatic, Electric, Hydraulic, others Applicable Instruments Position Switch, Positioners, Solenoid & other Relays Options Travel Indicator, Limit Stopper, Bellows seal, Special NDT *Different Trim are available upon reques

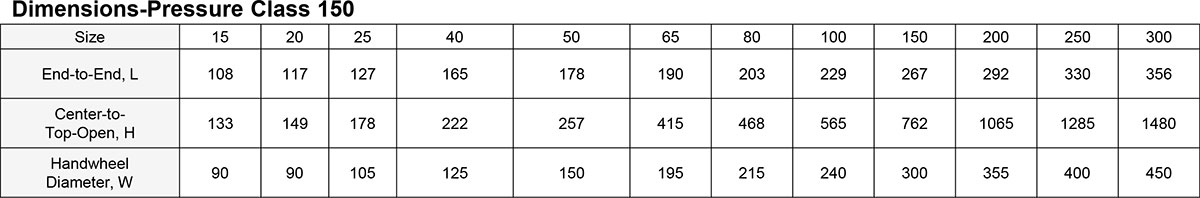

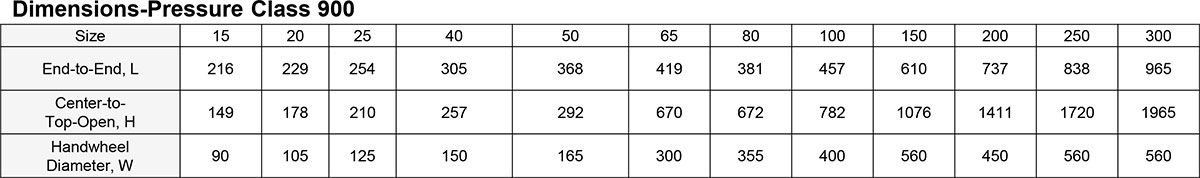

- Dimension Data

-