PRODUCT

Hyper-connection & Hyper-intelligence

Control System Leader

- PRODUCT

- Ball Valve

Ball Valve

Hyper-connection & Hyper-intelligence Control System Leader

-

- Ball valves are straight-through flow valves which provide positive shutoff with minimal pressure drop and flow turbulence. The barrier to flow is a ball which is rotated 90 degrees to the direction of flow.

- In floating ball valves, the ball has some freedom to move along the axis of the valve while having no freedom to rotate against the stem. when line pressure is applied to the closed ball, it moves slightly (or floats) downstream to maintain contact with the downstream seat where primary sealing occurs.

- Because the stem motion from full open to full closed is a 90 degree rotation, ball valves are ideally suited for automatic operation. they may generally be installed without regard for flow direction.

- TWO PIECE BODY BALL VALVE

-

- Globe style with high FL factor and flow paths with streamlined structure

- Top entry structure that can be applied to Contoured, Cage-balance, Pilot, and Disk Stact trim in metal and soft seat

- Various Rated Cvs and Customized Rated Cv can be applied to implement the. desired openning plan of the customer according to the special specifications

- In addition to basic EQ-%, Linear, and Quick Open flow characteristics, Customized Flow Characters can be applied to implement the desired flow characteristics of customers

- Customized valve can be manufactured to improve specific weakness of existing same type valve

- Applicable to the latest smart positioners as well as traditional P/P and E/P positioners with other instruments

- THREE PIECE BODY BALL VALVE

-

In three piece ball valves, the ball is held in a fixed axial position by upper and lower stems and can move only in a rotational mode. The resilient seats are contained in metal carriers which are spring loaded against the ball. Line pressure applied to a closed valve increases the spring load on the upstream seat to effect a tight seal. The primary seating is therefore on the upstream seat permitting ball valves to be used for “block and bleed” service.

- General Specification

-

Size Range 1/2" ~ 48" (other sizes are available) Pressure Range ASME 150 ~ 4500#, PN 10 ~ 420 Temperature Range -196 ~ 592℃ according to the material spec. Option : 815℃ Body Materials A216 WCB, A217 WC6, WC9, C12A

A351 CF8, CF8M, CF3M

A182 F51, F91, Inconel, Titanium & othersTrim Materials 316, 316L, 321, 410, 420(J2), 440C, 630, XM-19

Inconel. W-Co. Overay, Titanium & othersTrim Design Floating, Trunnion Mounted, Top Entry, Rising Stem Ball Seat Design Soft Seated, Metal Seated, FOS Function Seat surface Material Hard-Chrome, W.C.C, C.C.C, N.C.C, ENP, according to the Consultant factory Seak Leakage Class EN 12266-1 Rate "A", MSS SP-61, FCI 70-2. Class IV, V, according to the spec. Applicable Actuators Pneumatic, Electric Motor, Manual, others Applicable Instruments P/P & E/P & Smart Positioners. Solenoid & other Relays Options Handwheel, Limit Stopper, Special NDT *Different Trim are available upon request

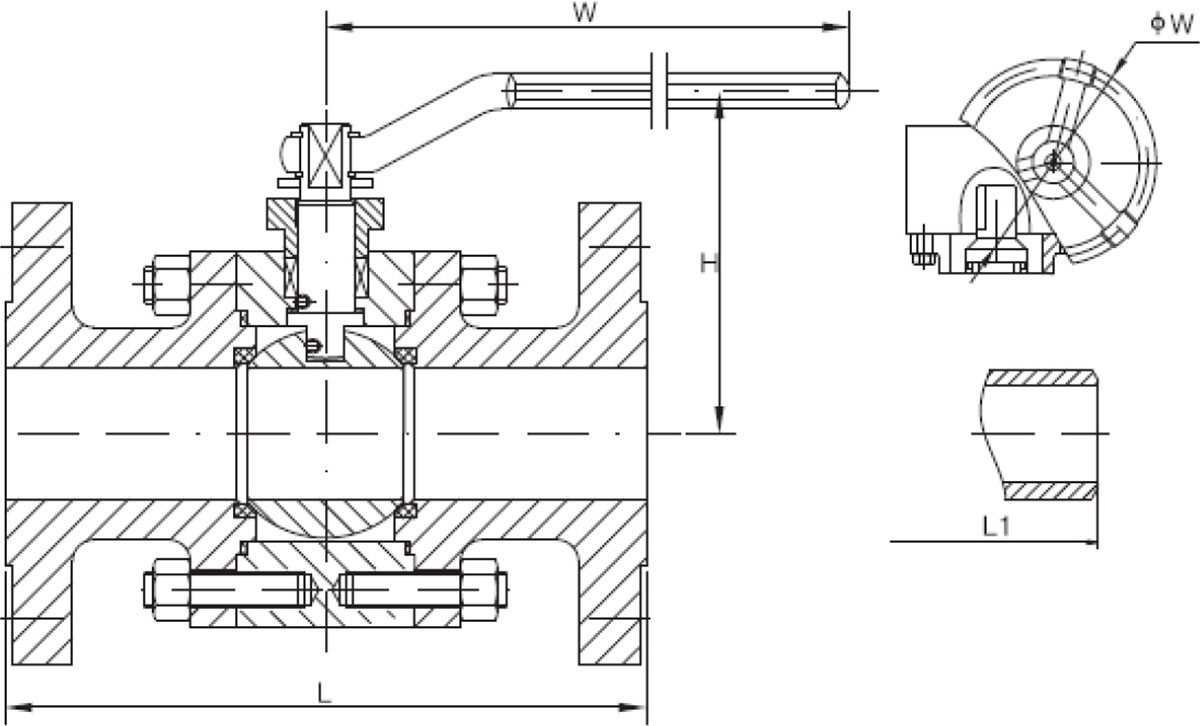

- Dimension Data

-